Pyrolysis roasting is a method of roasting coffee beans by heating them to induce chemical changes. It has the following characteristics compared to traditional roasting methods:

- Low-temperature roasting:

While conventional roasting methods take place at high temperatures above 180°C, pyrolysis roasting is conducted at a lower temperature of 100°C to 150°C.

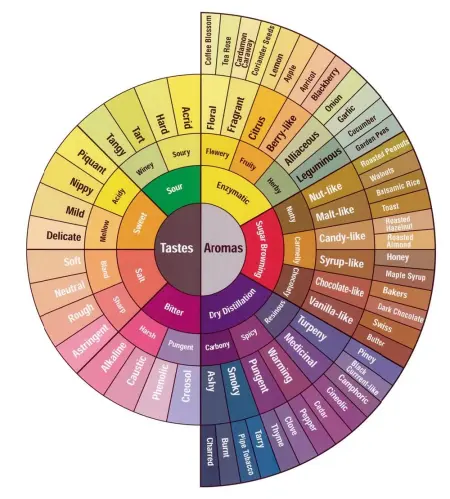

Lower temperatures reduce smoke emissions, decrease bitterness and acidity, and emphasize fruit and floral aromas.

- Long roasting time:

Due to the use of lower temperatures, the roasting time is significantly longer than traditional methods, taking up to 30 minutes or more.

The extended roasting time allows for even heat distribution throughout the beans, resulting in uniform roasting.

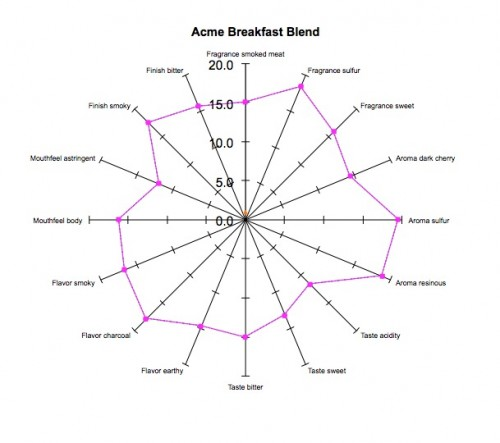

- Unique flavor profile:

Coffee roasted using the pyrolysis method has a unique flavor profile due to the low temperature and long roasting time.

It has a smoother and sweeter taste compared to traditionally roasted coffee, with reduced acidity.

- Advantages:

Reduced smoke emission: Environmental pollution reduction and worker health protection

Decreased bitterness and acidity: Smooth and sweet flavor

Enhanced fruit and floral notes: Aroma improvement

Uniform roasting: Improved bean quality

- Disadvantages:

Long roasting time: Decreased production efficiency

High initial investment cost: Equipment and technology development required

Skilled labor required: Importance of roasting process management

Types of Pyrolysis Roasting Methods:

Steam pyrolysis roasting: Uses steam to heat the beans.

Indirect pyrolysis roasting: Uses a heat transfer medium to heat the beans.

Vacuum pyrolysis roasting: Heats the beans in a vacuum state.

Suitable Subjects for Pyrolysis Roasting:

Coffee lovers who prefer a smooth and sweet flavor

Roasters who want to develop unique coffees

Businesses that want an environmentally friendly roasting method

Pyrolysis roasting is still a technology in its early stages, but it shows potential as a new approach to coffee roasting. It is expected to develop and become more widespread with technological advancements.

Additional Information:

Pyrolysis roasting technology: https://www.sciencedirect.com/topics/earth-and-planetary-sciences/roasting

Pyrolysis roasted coffee: https://library.sweetmarias.com/glossary/pyrolysis/